The Rise of 3D Printing: Revolutionizing Manufacturing and Design

3D printing has emerged as a game-changing technology, transforming the way we design, prototype, and manufacture objects. This innovative process, also known as additive manufacturing, has opened up new possibilities across various industries, from aerospace to healthcare. In this article, we'll explore the world of 3D printers, focusing on desktop models, resin printing machines, and multi-material printers, to help you understand their capabilities and potential applications.

What are desktop 3D printers and how do they work?

Desktop 3D printers are compact, affordable machines designed for home or office use. These devices create three-dimensional objects by layering materials such as plastic filaments, typically using a process called Fused Deposition Modeling (FDM). The printer heats and extrudes the filament through a nozzle, building the object layer by layer according to a digital 3D model. Desktop 3D printers have made additive manufacturing accessible to hobbyists, educators, and small businesses, enabling rapid prototyping and small-scale production.

How do resin printing machines differ from traditional 3D printers?

Resin printing machines, also known as stereolithography (SLA) printers, use a different technology than FDM printers. Instead of melting plastic filaments, these devices cure liquid resin using ultraviolet light. The process involves a resin tank with a transparent bottom and a build platform that moves up and down. As each layer is projected onto the resin, it hardens, and the platform rises slightly, allowing the next layer to form. Resin printing machines generally produce higher-resolution prints with smoother surfaces, making them ideal for detailed models, jewelry, and dental applications.

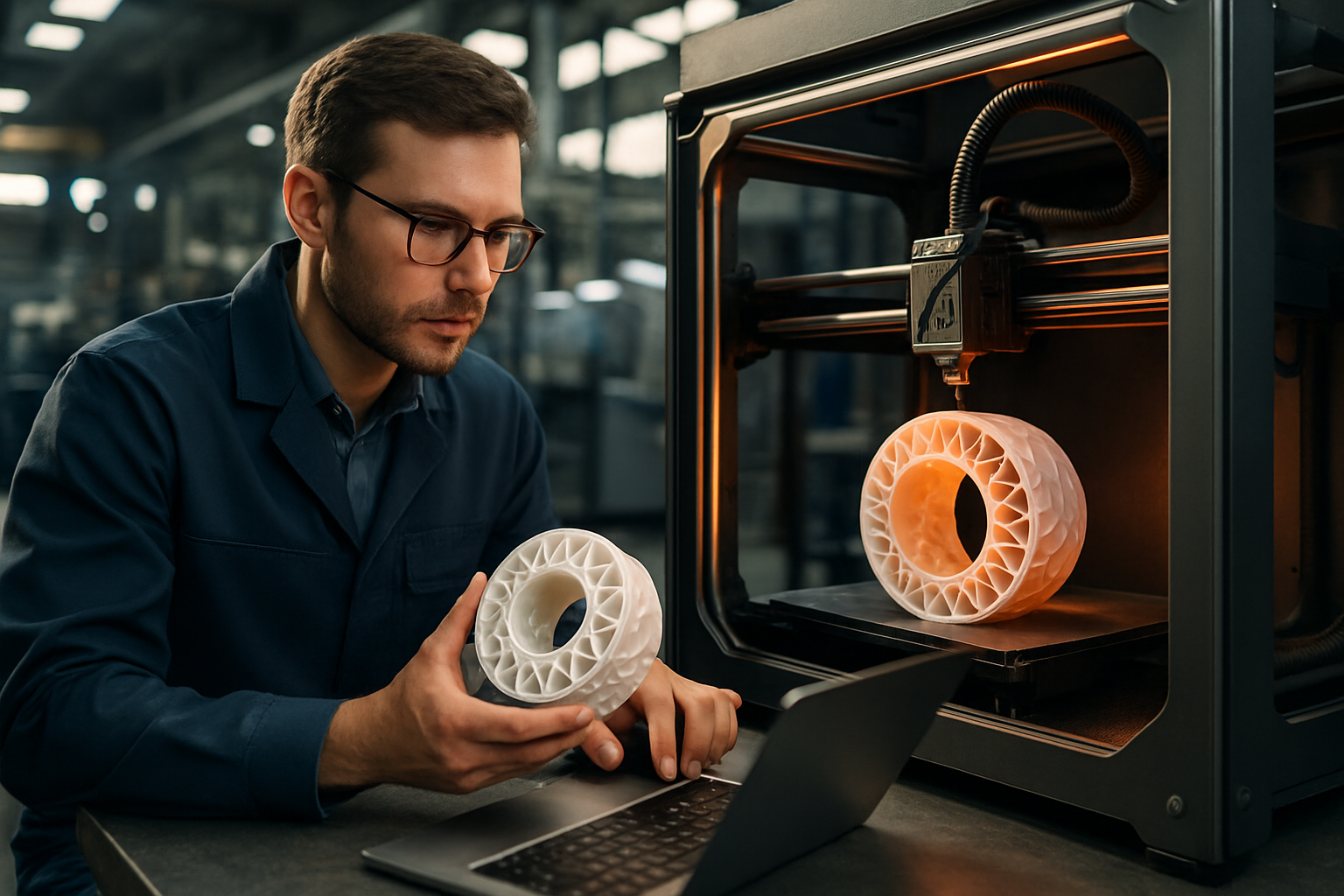

What are multi-material printers and why are they significant?

Multi-material printers represent the next evolution in 3D printing technology. These advanced machines can print objects using multiple materials simultaneously, allowing for complex combinations of colors, textures, and properties within a single print. This capability opens up new possibilities for creating functional prototypes, realistic models, and even end-use products with varying material characteristics. Multi-material printing is particularly valuable in industries such as automotive, where components may require both rigid and flexible parts, or in medical fields for creating anatomical models with different tissue densities.

What are the main applications of 3D printing technology?

3D printing has found applications across numerous industries, revolutionizing traditional manufacturing processes. In the automotive and aerospace sectors, it’s used for rapid prototyping and producing lightweight, complex parts. The medical field utilizes 3D printing for creating custom prosthetics, dental implants, and even bioprinting tissues. Architecture firms use the technology to create detailed scale models, while the fashion industry explores 3D-printed accessories and clothing. Education has also embraced 3D printing as a tool for hands-on learning in STEM subjects.

What are the current limitations and challenges of 3D printing?

While 3D printing has made significant strides, it still faces some limitations. Print speed remains a challenge, especially for larger objects or high-volume production. Material options, while expanding, are still limited compared to traditional manufacturing methods. The initial cost of high-end printers and materials can be prohibitive for some users. Additionally, the quality and strength of 3D-printed parts may not always match those produced by conventional methods, particularly for industrial applications. Overcoming these challenges is crucial for the wider adoption of 3D printing technology across industries.

How do different 3D printer types compare in terms of features and costs?

3D printers vary widely in terms of features, capabilities, and costs. Here’s a comparison of some popular types:

| Printer Type | Representative Model | Key Features | Cost Estimation |

|---|---|---|---|

| Desktop FDM | Prusa i3 MK3S+ | Easy to use, wide material compatibility | $750 - $1,000 |

| Resin (SLA) | Formlabs Form 3 | High detail, smooth surfaces | $3,500 - $4,000 |

| Multi-material | Prusa MMU2S | Prints with up to five materials | $300 (add-on to compatible printers) |

| Industrial FDM | Stratasys F370 | Large build volume, high-performance materials | $70,000 - $100,000 |

| Metal 3D Printer | EOS M 290 | Prints metal parts, industrial-grade | $250,000+ |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

3D printing technology continues to evolve rapidly, with new advancements expanding its capabilities and applications. As the technology becomes more accessible and affordable, it’s likely to play an increasingly important role in manufacturing, prototyping, and custom production across various industries. Whether you’re a hobbyist looking to explore desktop 3D printing or a business considering industrial-scale additive manufacturing, understanding the different types of 3D printers and their capabilities is crucial for making informed decisions and leveraging this transformative technology.