Discover the Strength and Applications of Polycarbonate Sheet Materials

Need strong, lasting material for your next project? This article explains how polycarbonate sheets perform in different environments. Discover why they’re chosen for roofing, signage and more. Learn about thickness, clarity and installation tips. Compare your options confidently.

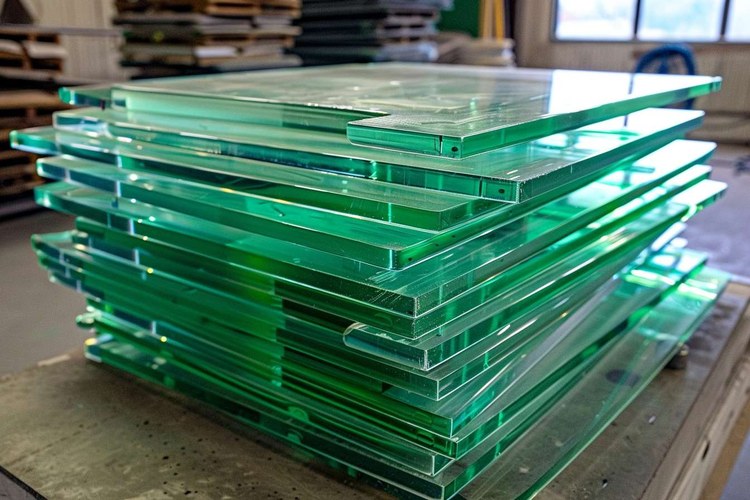

What are polycarbonate sheets and how are they made?

Polycarbonate sheets are thermoplastic polymers produced through a process called polymerisation. This involves combining various chemical compounds, primarily bisphenol A and phosgene, to create a strong, flexible material. The resulting plastic sheets can be manufactured in different thicknesses, colours, and surface finishes to suit various applications. The production process allows for the creation of both solid and multi-wall polycarbonate sheets, each with its own set of advantages.

What are the key properties of polycarbonate sheets?

Polycarbonate sheets boast an impressive array of properties that make them suitable for a wide range of applications:

-

High impact resistance: Polycarbonate is virtually unbreakable, with impact strength up to 250 times that of glass.

-

Lightweight: These plastic sheets are significantly lighter than glass or metal alternatives.

-

Temperature resistance: Polycarbonate can withstand temperatures from -40°C to 120°C without significant degradation.

-

UV resistance: Many polycarbonate sheets come with UV-protective coatings to prevent yellowing and degradation from sunlight exposure.

-

Optical clarity: Transparent polycarbonate sheets offer excellent light transmission, often comparable to glass.

-

Fire resistance: Some grades of polycarbonate sheets meet strict fire safety standards.

How do polycarbonate sheets compare to other materials?

When compared to other common building materials, polycarbonate sheets often come out on top in terms of versatility and durability:

-

Glass: Polycarbonate is much more impact-resistant and lighter than glass, making it safer and easier to handle.

-

Acrylic: While both are strong plastic sheets, polycarbonate offers superior impact resistance and heat tolerance.

-

PVC: Polycarbonate sheets are more transparent and have better UV resistance than PVC alternatives.

-

Metal: Polycarbonate is lighter, more easily shaped, and often more cost-effective than metal sheets for many applications.

What are the most common applications for polycarbonate sheets?

Polycarbonate sheets find use in a diverse range of industries and applications:

-

Construction: Roofing, skylights, greenhouse panels, and sound barriers

-

Automotive: Headlight lenses, interior panels, and windscreens for motorsports

-

Security: Bullet-resistant glazing, riot shields, and protective barriers

-

Signage: Illuminated signs, display cases, and outdoor advertising panels

-

Electronics: Protective covers for smartphones, tablets, and other devices

-

Industrial: Machine guards, safety screens, and equipment covers

What should you consider when choosing polycarbonate sheets?

When selecting polycarbonate sheets for your project in the United Kingdom, consider the following factors:

-

Thickness: Choose based on the required strength and rigidity for your application.

-

Surface finish: Options include smooth, textured, or anti-reflective coatings.

-

UV protection: Ensure adequate UV resistance for outdoor applications.

-

Fire rating: Check local building regulations for required fire safety standards.

-

Colour and transparency: Select from clear, tinted, or opaque options as needed.

-

Installation method: Consider the compatibility with your existing structures and support systems.

How do different polycarbonate sheet products compare?

When comparing polycarbonate sheet products, it’s essential to consider factors such as thickness, UV protection, and specific features. Here’s a comparison of some popular options available in the UK:

| Product | Manufacturer | Thickness | UV Protection | Key Features | Estimated Cost (per m²) |

|---|---|---|---|---|---|

| Makrolon® GP | Covestro | 2-15mm | Optional | High impact resistance, optical clarity | £20-£80 |

| LEXAN™ MARGARD™ | SABIC | 3-12mm | Yes | Abrasion resistant, anti-graffiti | £40-£120 |

| Polycarb™ | Brett Martin | 2-16mm | Yes | 10-year warranty, fire-rated options | £25-£90 |

| Marlon ST | Brett Martin | 4-40mm | Yes | Multiwall structure, thermal insulation | £15-£60 |

| PALSUN® | Palram | 1.5-15mm | Yes | Wide range of colours and textures | £30-£100 |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

In conclusion, polycarbonate sheets offer a unique combination of strength, versatility, and durability that makes them an excellent choice for a wide range of applications. From construction to automotive manufacturing, these strong panels provide solutions that other materials often can’t match. By considering factors such as thickness, UV protection, and specific product features, you can select the ideal polycarbonate sheet material for your project needs.