Cartoning Machines: Revolutionizing Packaging Efficiency in Canada

In the fast-paced world of manufacturing and packaging, cartoning machines have become an indispensable tool for businesses across Canada. These automated systems streamline the process of forming, filling, and sealing cartons, significantly boosting productivity and ensuring consistent packaging quality. As companies strive to meet growing consumer demands and maintain competitive edges, understanding the capabilities and benefits of cartoning machines is crucial for those in the packaging industry.

What is a cartoning machine and how does it work?

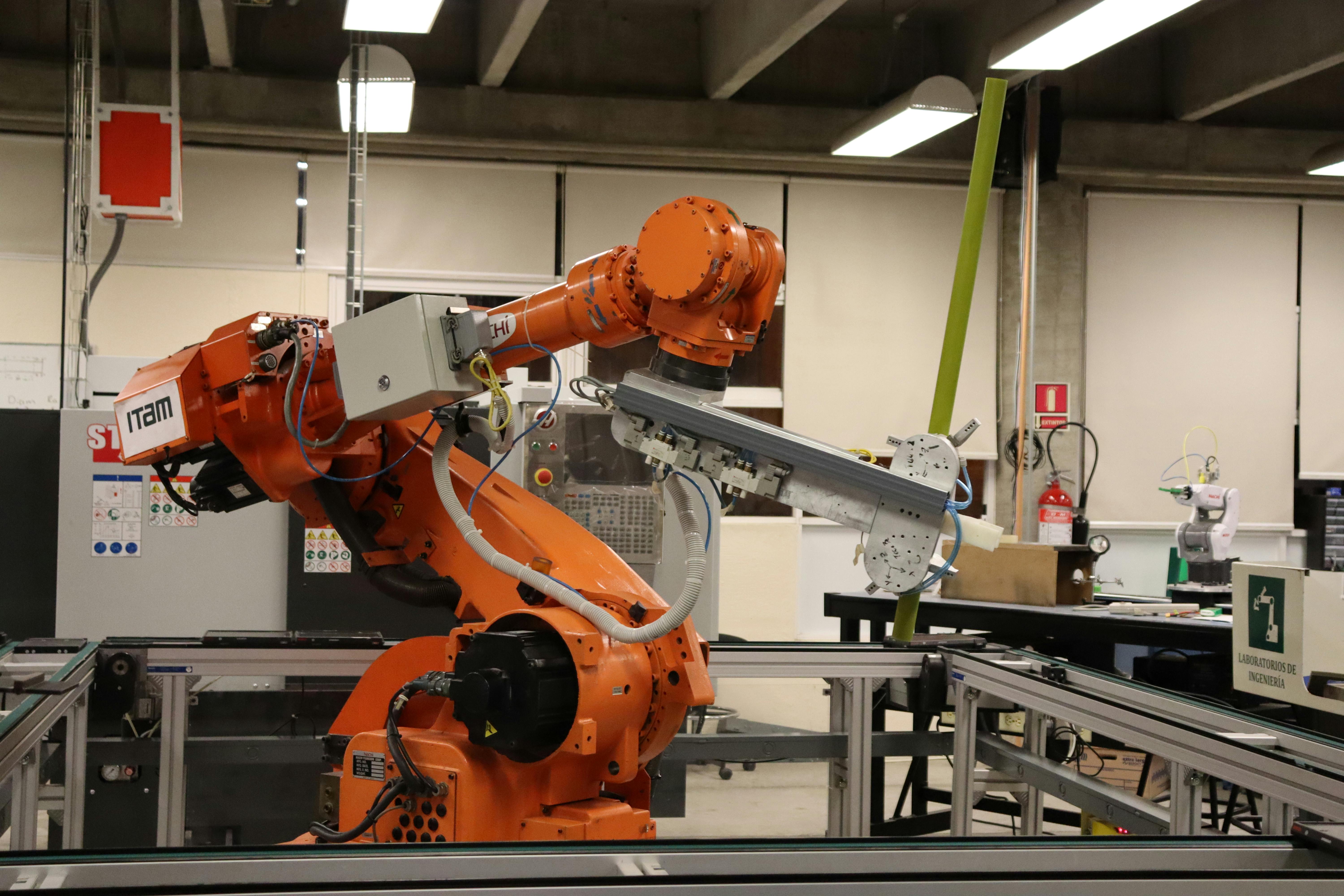

A cartoning machine, also known as a carton packaging machine, is an automated system designed to form, fill, and seal cartons with various products. These machines typically operate in a continuous motion, efficiently handling multiple steps of the packaging process. The basic workflow involves feeding flat carton blanks into the machine, which then forms them into three-dimensional boxes. Products are then inserted into the cartons, and finally, the boxes are sealed and ejected for further processing or shipping.

What are the key benefits of using automated cartoning systems?

Implementing an automated cartoning system offers numerous advantages for businesses in Canada. Firstly, these machines significantly increase production speed and efficiency, allowing companies to handle larger volumes of products in less time. They also ensure consistent packaging quality, reducing human error and minimizing product damage. Additionally, cartoning machines can adapt to various carton sizes and product types, providing flexibility for different packaging needs. By automating the cartoning process, businesses can also reduce labor costs and allocate human resources to more complex tasks.

What types of industries commonly use carton forming machines?

Carton forming machines find applications across a wide range of industries in Canada. The food and beverage sector heavily relies on these machines for packaging items such as cereals, snacks, and frozen foods. Pharmaceutical companies use cartoning systems to package medications and medical supplies with precision and compliance to strict regulations. The cosmetics industry also benefits from these machines for packaging various beauty and personal care products. Other sectors that frequently employ cartoning machines include electronics, household goods, and consumer products.

How do cartoning machines contribute to sustainability efforts?

In an era of increasing environmental awareness, cartoning machines play a crucial role in supporting sustainability initiatives. These automated systems often result in reduced material waste compared to manual packaging processes. Many modern cartoning machines are designed to work with eco-friendly packaging materials, including recyclable and biodegradable cartons. Additionally, the precision of these machines helps minimize overpackaging, thereby reducing the overall environmental footprint of packaged products. By optimizing packaging efficiency, cartoning machines also contribute to reduced energy consumption and transportation costs.

What are some unique features of modern cartoning machines in Canada?

Cartoning machines available in the Canadian market boast several innovative features that set them apart. Many modern systems incorporate advanced sensors and vision systems for quality control, ensuring that only properly formed and filled cartons proceed through the packaging line. Some machines offer quick-change tooling, allowing for rapid transitions between different carton sizes or product types. Additionally, Industry 4.0 integration is becoming increasingly common, with cartoning machines capable of real-time data collection and analysis for improved process optimization and predictive maintenance.

How do different cartoning machine models compare in terms of features and pricing?

When considering cartoning machines for your business in Canada, it’s essential to compare different models based on their features, capabilities, and cost. Here’s a comparison of some popular cartoning machine models available in the Canadian market:

| Model | Manufacturer | Speed (cartons/min) | Carton Size Range | Key Features | Estimated Price Range (CAD) |

|---|---|---|---|---|---|

| CM-100 | PackTech | 60-100 | 50-250mm (L,W,H) | Quick changeover, touchscreen interface | $75,000 - $100,000 |

| AutoCart 2000 | CanadaPack | 80-120 | 80-300mm (L,W,H) | Multi-product feeding, servo-driven | $100,000 - $150,000 |

| FlexiCart Pro | GlobalMach | 100-150 | 60-400mm (L,W,H) | Modular design, remote diagnostics | $150,000 - $200,000 |

| RapidForm X5 | BoxTech | 150-200 | 40-350mm (L,W,H) | High-speed operation, AI-powered quality control | $200,000 - $300,000 |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

In conclusion, cartoning machines have become essential tools for businesses seeking to enhance their packaging operations in Canada. These automated systems offer significant benefits in terms of efficiency, consistency, and sustainability. As technology continues to advance, we can expect even more innovative features and capabilities in future cartoning machine models, further revolutionizing the packaging industry across the country.