Cartoning Machines: Essential Equipment for Efficient Packaging

Cartoning machines are integral to modern packaging operations, streamlining the process of encasing products in cardboard containers. These versatile machines are used across various industries, from food and pharmaceuticals to consumer goods and electronics. In this comprehensive guide, we'll explore the world of cartoning machines, their types, applications, and the benefits of investing in both new and used equipment.

What is a cartoning machine and how does it work?

A cartoning machine is an automated packaging device designed to form, fill, and seal cardboard cartons or boxes. The machine typically operates in a series of steps:

-

Carton formation: Flat cardboard blanks are picked from a magazine and formed into three-dimensional boxes.

-

Product insertion: The product is placed into the carton, either manually or through automated feeding systems.

-

Closing and sealing: The carton flaps are folded and sealed using adhesive, heat-sealing, or mechanical locking methods.

These machines can handle various carton styles, including end-load, top-load, and wraparound configurations, adapting to different product shapes and sizes.

What are the main types of cartoning machines?

Cartoning machines come in several configurations to suit different packaging needs:

-

Horizontal cartoning machines: Ideal for products that can be easily loaded from the side, such as bottles, pouches, or blister packs.

-

Vertical cartoning machines: Suitable for products that are best loaded from the top, like granular or powdered goods.

-

Continuous motion cartoners: High-speed machines for large-scale production, offering seamless operation.

-

Intermittent motion cartoners: More versatile machines that stop briefly during each cycle, allowing for complex product handling.

Each type has its advantages, and the choice depends on factors like product characteristics, production speed requirements, and available floor space.

What industries benefit most from cartoning machinery?

Cartoning machines find applications across numerous industries:

-

Food and beverage: Packaging cereals, snacks, frozen foods, and dairy products.

-

Pharmaceuticals: Encasing pills, vials, and medical devices in secure, tamper-evident cartons.

-

Personal care: Packaging cosmetics, toiletries, and hygiene products.

-

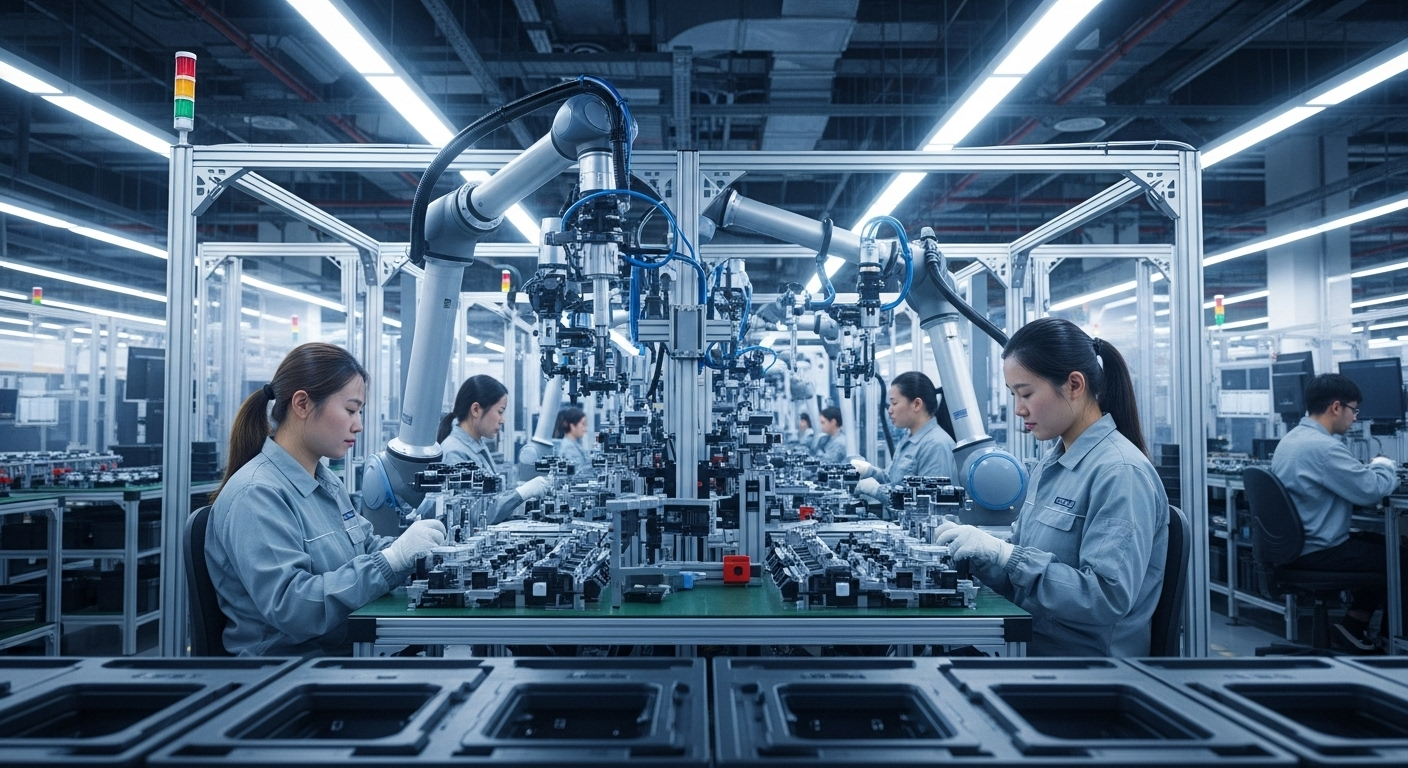

Electronics: Protecting small electronic devices and components.

-

Household goods: Packaging cleaning products, accessories, and small appliances.

The versatility of cartoning machines makes them invaluable in any industry where products need to be efficiently and securely packaged in cardboard containers.

What are the advantages of investing in a cartoning machine?

Implementing cartoning machinery in your packaging line offers several benefits:

-

Increased productivity: Automated cartoning significantly speeds up the packaging process compared to manual methods.

-

Improved consistency: Machines ensure uniform carton formation and sealing, enhancing product presentation.

-

Reduced labor costs: Automation reduces the need for manual packaging staff, potentially lowering overall operational expenses.

-

Enhanced product protection: Precise carton formation and sealing provide better protection during storage and transportation.

-

Flexibility: Modern cartoning machines can often handle multiple carton sizes and styles with quick changeovers.

These advantages contribute to improved efficiency, reduced waste, and potentially higher profit margins for businesses across various sectors.

What should you consider when choosing between new and used cartoning machines?

When deciding between new and used cartoning machines, several factors come into play:

-

Budget: Used machines often come at a lower initial cost, making them attractive for businesses with limited capital.

-

Production needs: New machines may offer higher speeds and more advanced features, suitable for growing businesses or those with specific requirements.

-

Availability: Used machines might be readily available, while new machines could have longer lead times.

-

Warranty and support: New machines typically come with full warranties and manufacturer support, whereas used machines may have limited or no warranty.

-

Energy efficiency: Newer models often incorporate energy-saving features, potentially reducing long-term operational costs.

It’s essential to carefully evaluate your specific needs, budget constraints, and long-term goals when choosing between new and used cartoning equipment.

How do you maintain and optimize cartoning machine performance?

To ensure optimal performance and longevity of your cartoning machine:

-

Regular cleaning: Remove product residue and dust to prevent buildup and maintain smooth operation.

-

Lubrication: Follow the manufacturer’s guidelines for lubricating moving parts to reduce wear and tear.

-

Preventive maintenance: Schedule regular inspections and maintenance to catch potential issues early.

-

Operator training: Ensure staff are properly trained in machine operation and basic troubleshooting.

-

Software updates: For machines with digital controls, keep software up to date for optimal performance and security.

-

Quality control checks: Regularly inspect output to ensure consistent carton formation and sealing.

By implementing a robust maintenance program, you can maximize the lifespan and efficiency of your cartoning machinery, whether new or used.

| Cartoning Machine Type | Typical Application | Speed Range (cartons/minute) | Estimated Cost Range (CAD) |

|---|---|---|---|

| Horizontal Cartoner | Pharmaceuticals | 60-300 | $100,000 - $500,000 |

| Vertical Cartoner | Powdered Foods | 30-120 | $80,000 - $300,000 |

| Continuous Motion | High-volume Beverage | 200-600 | $300,000 - $1,000,000 |

| Intermittent Motion | Personal Care Items | 40-150 | $150,000 - $400,000 |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Cartoning machines are essential for businesses looking to streamline their packaging processes. Whether opting for a new, state-of-the-art model or a cost-effective used machine, the right cartoning equipment can significantly boost productivity and product presentation. By understanding the types, applications, and maintenance requirements of these machines, businesses can make informed decisions to enhance their packaging operations and stay competitive in today’s fast-paced market.